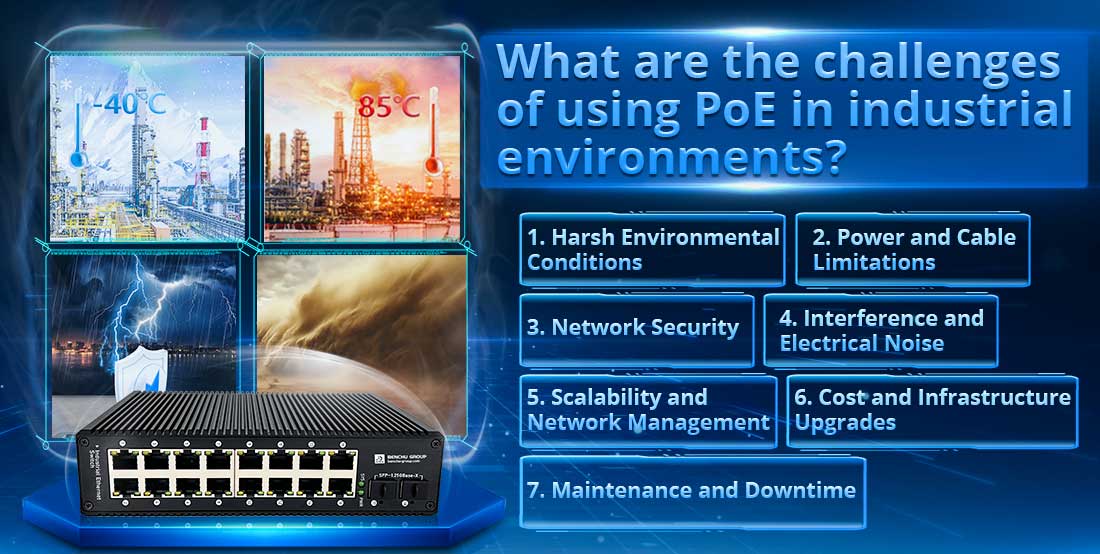

Using Power over Ethernet (PoE) in industrial environments offers numerous advantages, but it also comes with specific challenges due to the harsh and demanding conditions often found in these settings. Here are the key challenges associated with deploying PoE in industrial environments:

1. Harsh Environmental Conditions

Temperature Extremes: Industrial environments often experience extreme temperatures, from high heat near machinery to freezing conditions in outdoor installations. Standard PoE switches and devices may not be designed to withstand these extremes, leading to malfunctions or failure.

--- Solution: Use industrial-grade PoE switches and devices that are built to operate in a wide temperature range, typically from -40°C to 75°C (-40°F to 167°F).

Dust, Moisture, and Corrosion: Factories, warehouses, and outdoor installations are exposed to dust, dirt, moisture, and chemicals, which can damage PoE equipment over time.

--- Solution: Use IP-rated enclosures for PoE switches and devices to protect them from dust and water ingress. Look for equipment with corrosion-resistant components or sealed enclosures.

Vibration and Shock: Equipment in industrial settings is often subject to vibration from nearby machinery or transport systems. Standard PoE equipment may not be able to tolerate this, leading to disconnections or hardware damage.

--- Solution: Deploy ruggedized PoE switches and devices specifically designed to withstand high vibration and shock.

2. Power and Cable Limitations

Distance Limitations: PoE has a maximum cable length of 100 meters (328 feet) due to the limitations of Ethernet cables. In large industrial environments, devices may be located far from network switches, making it difficult to deliver both power and data over standard distances.

--- Solution: Use PoE extenders or industrial PoE repeaters to increase the range of Ethernet cables beyond 100 meters, or consider fiber-optic PoE solutions combined with media converters to extend the network over long distances.

Power Consumption: In some industrial environments, devices like IP cameras, sensors, or lighting systems may require higher power than standard PoE can provide. Industrial equipment often needs more power than what is offered by PoE (15.4W) or PoE+ (30W).

--- Solution: Utilize PoE++ (IEEE 802.3bt), which delivers up to 60W or 100W per port, sufficient for higher-power industrial devices such as motorized IP cameras, high-powered access points, and industrial lighting systems.

3. Network Security

Unauthorized Access to PoE Devices: In industrial environments, network devices such as IP cameras, sensors, and access points may be located in publicly accessible or vulnerable areas, increasing the risk of unauthorized tampering or network breaches.

--- Solution: Implement network security protocols, such as VLANs (Virtual Local Area Networks) to segment traffic, and 802.1X authentication to ensure only authorized devices are connected to the PoE network.

Cybersecurity Threats: Industrial environments increasingly rely on IoT devices connected through PoE, making them targets for cyberattacks. Compromised PoE devices can lead to system breaches or data loss.

--- Solution: Use managed PoE switches with built-in security features like firewalls, intrusion detection systems, and remote monitoring to detect and prevent security threats.

4. Interference and Electrical Noise

Electromagnetic Interference (EMI): Industrial environments are often filled with heavy machinery, motors, and electrical equipment that generate EMI or RF interference, which can disrupt the data signals in Ethernet cables, especially when running long distances.

--- Solution: Use shielded twisted-pair (STP) Ethernet cables and EMI-hardened switches to minimize interference and maintain stable data transmission.

Power Surges and Fluctuations: Factories and industrial plants may experience power surges or unstable power supplies, which can damage sensitive PoE devices.

--- Solution: Install surge protectors and use PoE switches with power redundancy and uninterruptible power supplies (UPS) to protect devices from power fluctuations and ensure continued operation during outages.

5. Scalability and Network Management

Expanding the Network: Industrial facilities often grow or change over time, requiring the addition of more PoE devices. However, managing and scaling a large PoE network in an industrial setting can be complex, especially when dealing with mixed environments that include legacy devices and newer PoE-enabled equipment.

--- Solution: Use modular PoE switches that allow for expansion as more devices are added. Implement centralized management tools for PoE switches to monitor and control power delivery and data traffic across the network.

High Device Density: Some industrial environments have a high density of PoE devices, such as sensors and cameras, all of which need reliable power and data connectivity. This can strain the PoE switch's power budget or create data bottlenecks.

--- Solution: Choose high-power PoE switches with a larger PoE power budget to handle more devices. Also, implement QoS (Quality of Service) settings to prioritize critical traffic like video streaming from IP cameras or real-time sensor data.

6. Cost and Infrastructure Upgrades

Higher Initial Costs: Industrial-grade PoE switches, ruggedized cables, and protective enclosures are typically more expensive than standard networking equipment. Additionally, upgrading older network infrastructure to support PoE can involve significant costs.

--- Solution: While initial costs are higher, PoE can still reduce long-term expenses by eliminating the need for separate power lines and power supplies. It's important to carefully plan and budget for the infrastructure upgrades required to support an industrial PoE network.

7. Maintenance and Downtime

Frequent Maintenance: Industrial environments often require more frequent maintenance due to harsh conditions, physical damage to cables, and the need to ensure continuous operation. Unplanned downtime can result in significant operational losses.

--- Solution: Regularly inspect cables, connectors, and devices for signs of wear and tear. Use managed PoE switches that allow for remote monitoring, making it easier to identify potential issues before they lead to network downtime.

Conclusion:

While PoE technology can offer significant benefits in industrial environments, such as simplified power and data delivery, it also presents challenges. These include harsh environmental conditions, power limitations, network security risks, interference, and scalability concerns. However, with proper planning and the use of ruggedized, industrial-grade equipment, surge protection, and network management tools, many of these challenges can be effectively addressed to ensure a reliable, efficient PoE network in demanding industrial settings.