At BENCHU GROUP, we pride ourselves on being a trusted OEM/ODM switches manufacturer with extensive experience in the industry. Our factory is equipped with state-of-the-art machinery and cutting-edge technology that allows us to produce high-quality networking products, tailored to our clients’ specific needs. We have a dedicated team of engineers, skilled in product design, development, and production, ensuring innovative and reliable solutions. With ISO9001 and ISO14001 certifications, strict quality control processes, and a capacity for large-scale manufacturing, we provide consistent, dependable products that meet international standards.

Our in-house R&D team collaborates with clients to develop customized solutions, from hardware design to firmware integration. We also offer a wide range of customization services, including appearance, functionality, and packaging. Our commitment to flexibility and client satisfaction ensures that we can adapt quickly to changing market demands, delivering efficient turnaround times while maintaining competitive pricing.

With 9 years of manufacturing experience, BENCHU GROUP has built a strong reputation for reliability, quality, and professionalism, providing tailored solutions that help our partners grow their businesses. Clients who choose to collaborate with us gain a trusted partner focused on their success, supported by a dedicated after-sales team . Trust in BENCHU GROUP to deliver high-quality, innovative switch products that meet your every requirement.

-

Factory

Delivering reliable, future-proof solutions through OEM/ODM services, tailored to the specific needs of our global clients.

-

Development Department

R&D team is continuously focused on innovation, driving the creation of forward-thinking products that keep the company at the cutting edge of the industry.

-

Technology Department

A expertise technical and support team ensures product reliability, providing long-term stability and seamless operation.

-

Switches Workshop

A skilled workforce of over 50 professionals, each with more than three years of experience, guarantees production stability and consistency.

-

Switches Workshop

By experienced personnel, we are able to meet the demands of large-scale production while maintaining superior quality across all products.

-

Optical Module Workshop

State-of-the-art, professional dust-free optical module production workshop, designed to meet the highest industry standards for cleanliness and precision.

-

SMT

Our SMT line employs cutting-edge machinery that accurately positions tiny surface-mount components onto the PCBs, ensuring reliability and efficiency.

-

Reflow Soldering

The reflow soldering process further enhances the integrity of our assemblies by melting solder paste and securing components to the boards with precision.

-

Plug-in

The plug-in production line allows for precise component assembly, where skilled technicians meticulously place and secure electronic components onto printed circuit boards (PCBs).

-

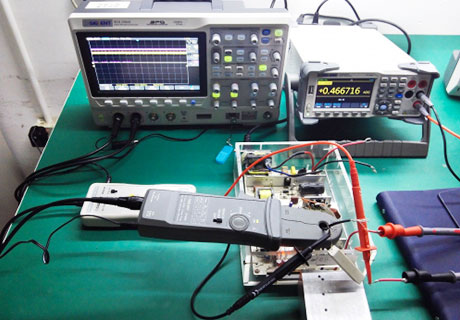

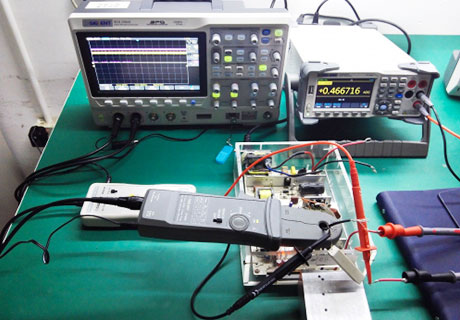

Laboratory

Comprehensive laboratory designed to ensure the highest standards of product quality.

-

Laboratory

Advanced testing and diagnostic tools that allow us to rigorously assess every product through each phase of development.

-

Laboratory

Stress testing, performance verification, and quality assurance processes tailored to meet industry standards.

-

Aging Room

By maintaining a controlled environment for testing, we ensure that every product meets both regulatory and customer-specific requirements, ensuring reliable and high-performing results.

-

Test Stand

Custom-designed tools that are easy to use can significantly enhance productivity.

-

Switches Testing

Comprehensive testing ensures that every product meets the highest quality standards, guaranteeing a 100% qualification rate before delivery.

-

-

Handmade Printing (Customized Brand)

Our design services cover every aspect of brand visualization, from unique logos to packaging, ensuring consistency and alignment with the brand's core values.

-

Customized Labels(Customized Brand)

Through personalized design solutions, we empower brands to establish a memorable and deeply ingrained identity in their respective markets.

-

Electronic Material Warehouse

The warehouse’s efficient layout and climate control ensure that sensitive electronic materials are stored in optimal conditions, preserving their quality.

-

Accessories Warehouse

With its efficient layout, the warehouse supports smooth production processes by ensuring that the right accessories are available whenever needed, contributing to overall operational efficiency.

-

Packaging Material Warehouse

The Packaging Material Warehouse is responsible for storing all necessary materials used in the final stage of production, such as boxes, labels, tapes, and protective wraps.

-

-

Packing

In line with transportation needs, we employ various packaging techniques to safeguard products and ensure they reach their destination securely.

-

Packing

In line with transportation needs, we employ various packaging techniques to safeguard products and ensure they reach their destination securely.

-

Transport

By assessing customer requirements, we choose the most efficient transportation methods to reduce shipping costs while ensuring the safe delivery of products.

-

Transport

By assessing customer requirements, we choose the most efficient transportation methods to reduce shipping costs while ensuring the safe delivery of products.

-

Transport

By assessing customer requirements, we choose the most efficient transportation methods to reduce shipping costs while ensuring the safe delivery of products.